Slug Flow

Slug Flow

Production and processing systems are designed to operate, as much as possible, in a stable manner. Different multiphase flow regimes have different degrees of intermittency. Slug flow is characterized by the alternate passage of portions of liquid and gas pockets, which may induce large variations in liquid and gas flow rates and thereby compromisse the operability of the processing plant (separator flooding, cycling of compressor, etc). Slugs may also travel at high velocities, and long slugs may possess considerable momentum. This can compromise mechanical integrity of pipework and equipment, which can cause repeated repair and maintenance costs or even lead to catastrophic events.

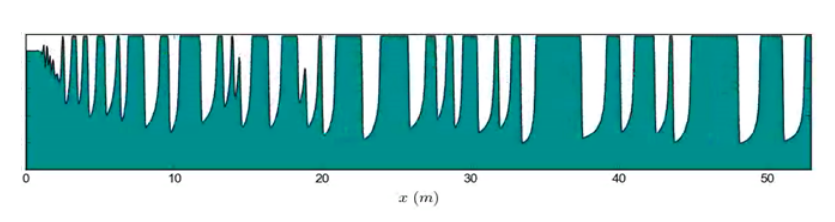

Slug flow may occur as a natural flow regime (“hydrodynamic slugging”), as a result of flow transients (e.g. well start-up or pigging operation) or, as a consequence of terrain features (“terrain-slugging” or “riser slugging”). When associated to flowline-riser geometries, the later is commonly referred to as severe slugging and is often taken as the most critical slugging regime. Hydrodynamic slug flow per se is not necessarily a problem, and, in fact, it is a very common flow pattern observed in production pipelines. However, in some cases, a few slugs may grow in length, achieving several hundreds of pipe diameters, which may also cause a severe slugging problem. Ideally, in any type of slugging designers and operators should be able to accurately predict the distribution of slug and bubble lengths, their velocities and frequencies intrinsically, without resorting excessively to empirical correlations, which is not possible with traditional methods. The uncertainty in these methods can have a significant influence on the design (size, weight) and operation of slug catching systems or separators. The potential benefits of more accurate design practices include, for example, savings in CAPEX by avoiding conservatism. Better predictions of slug parameters can also potentially improve operational practices and reduce associated costs.

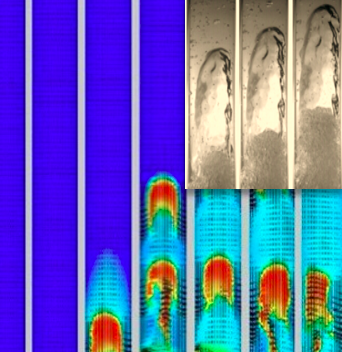

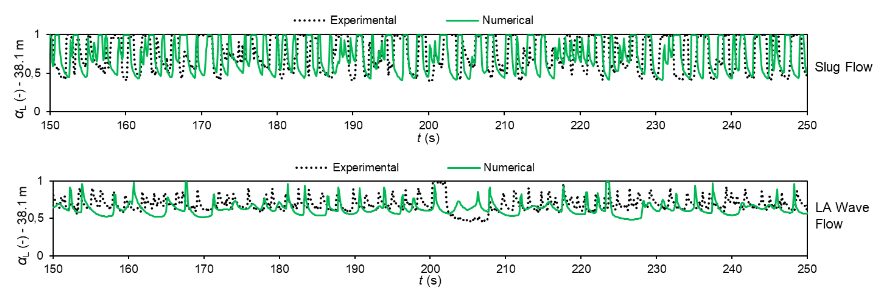

ISDB FlowTech has worked for many years on the development of better modeling concepts for multiphase flow (such as slug or regime capturing methods; see Figs above) in order to improve accuracy and predictability of existing flow simulators.

Publications:

Ayati, A.A., Carneiro, J.N.E., 2018. Statistical characterization of interfacial waves in turbulent stratified gas-liquid pipe flows. International Journal of Multiphase Flow. (in Press)

Nieckele, A.O., Carneiro, J.N.E., 2017. On the numerical modeling of slug and intermittent flows in oil and gas production. In: ASME 36th International Conference on Ocean, Offshore and Artic Engineering, Trondheim, Norway, 25-30 June.

Pasqualette, M.A., Carneiro, J.N.E., Nieckele, A.O., Johansen, S.T., 2017. Optimization of the interfacial shear stress for the simulation of horizontal viscous oil-gas flows with the 1D Two-Fluid Model. In: V Journeys in Multiphase Flows, São Paulo, Brazil, 27-31 March.

Pasqualette, M.A., Carneiro, J.N.E., Nieckele, A.O., Johansen, S.T., 2015. Numerical simulation of horizontal viscous oil-gas flows in the stratified and slug regimes with the 1D Two-Fluid Model. In: IV Journeys in Multiphase Flows, Campinas, Brazil, 23-27 March.

Simões, E.F., Carneiro, J.N.E., Nieckele, A.O., 2014. Numerical prediction of non-boiling heat transfer in horizontal stratified and slug flow by the Two-Fluid Model. International Journal of Heat and Fluid Flow, 47: 135-145.

Nieckele, A.O., Carneiro, J.N.E., Chucuya, R.C., Azevedo, J.H.P., 2013. Initiation and statistical evolution of horizontal slug flow. ASME Journal of Fluids Engineering, 135(12): 121302.

Carneiro, J.N.E., Fonseca, R., Ortega, A.J., Chucuya, R.C., Nieckele, A.O., Azevedo, L.F.A., 2011. Statistical characterization of two-phase slug flow in a horizontal pipe. Journal of the Brazilian Society of Mechanical Sciences and Engineering, 33(1): 251-258.