CO2

CO2

Recently, the petroleum industry has been facing challenges to develop and operate fields with high CO2 contents. In the case of many Brazilian pre-salt fields (e.g. Libra, Jupiter, Lula, among others), huge volumes of associated gas with significant CO2 molar fractions are produced at high pressures and need to be handled by the offshore systems. After separation from the natural gas, a CO2-rich stream can be compressed and re-injected for Enhanced Oil Recovery (EOR) into the reservoir (even in cases where oil recovery increase is not significant, venting to the atmosphere is usually avoided for HSE reasons). The separation and compression may be performed topside or subsea. In either case, a further increase in CO2 content may occur in the production streams with field life time.

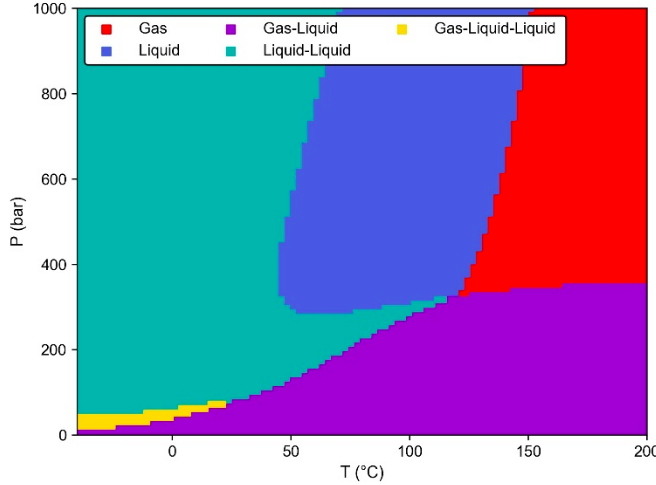

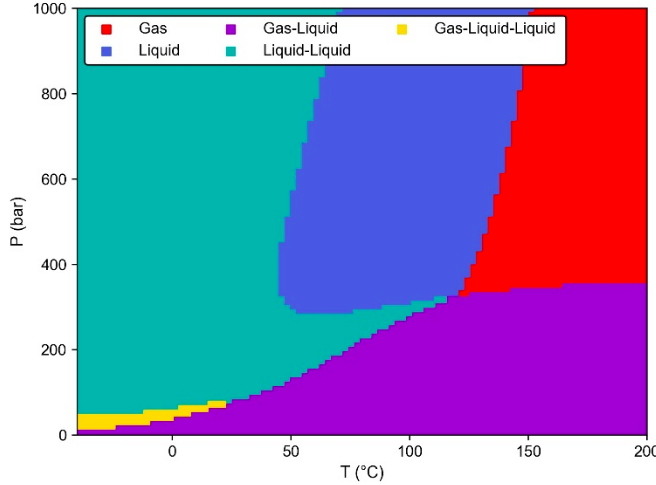

From a thermodynamic perspective, the presence of CO2 may give rise to a complex phase behavior, inducing the appearance of LLE (Liquid-Liquid Equilibria) and VLLE (Vapor-Liquid-Liquid Equilibria) for relevant conditions of temperature-pressure. The presence of water contributes to the increase in complexity. The formation of solids must also be carefully considered during design and operation of CO2 rich systems, for various reasons, amongst which we may cite: in high GOR and high CO2 cases, cooling may be augmented due to increased Joule-Thomson effect; deep water fields may operate under high pressure and low temperature environments, increasing hydrate risks; solid CO2 may form topside due to low temperatures observed when depressuring CO2-rich streams, etc.

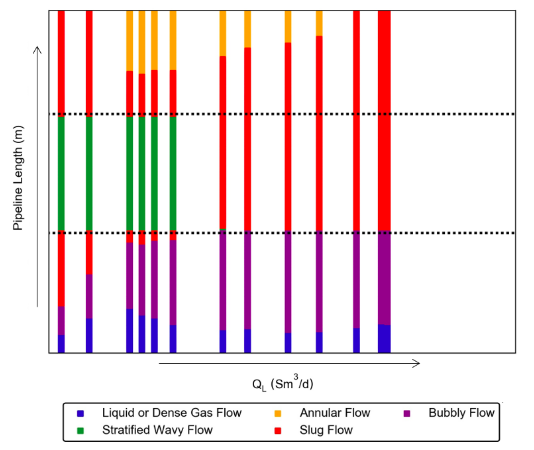

From the perspective of the flow of high pressure CO2-rich hydrocarbon streams, a few aspects related to the physical properties may also be highlighted: presence of a dense phase, low relative densities between light and heavy phases, low Interfacial Tension and phase identification criteria issues. These characteristics may have an important impact on the expected flow patterns and closure models in flow simulators for wells, flowlines, risers and related equipment. Furthermore, as mentioned above, complex phase behavior is expected, which needs to be handled with both PVT lookup tables and compositional models.

As a consequence, both from the point of view of surface processing (safety systems, materials selection, corrosion, etc) and of flow through wells, flowlines, risers and ancillary equipment, commercial simulators must be verified, validated and improved for hydrocarbons mixtures with high CO2 contents and CO2 streams with and without impurities. In the present project, we currently focus at evaluating 1D and CFD models for current and future production scenarios and develop new concepts/tools for the modeling and simulation of such flows.

FIGURE 2 – Flow pattern predictions for a production pipeline with high CO2-content for several liquid volumetric flow rates at standard conditions (QL).

Publications:

Rempto, M. J., Pasqualette, M.A., Fontalvo, E.M.G., Carneiro, J.N.E., Fonseca, R., Ciambelli, J.R.P., Johansen, S.T., Løvfall, B.T., 2018. High CO2 content effect on the flow of crude oils in production transient operations. In: 11th North American Conference on Multiphase Production Technology, Banff, Canada, 6-8 June.

Pasqualette, M.A., Rempto, M.J., Carneiro, J.N.E., Fonseca, R., Ciambelli, J.R.P., Johansen, S.T., Løvfall, B.T., 2017. Parametric study of the influence of GOR and CO2 content on the simulation of a pre-salt field configuration. In: Offshore Technology Conference, Rio de Janeiro, Brazil, 24-26 October.

Carneiro, J.N.E., Pasqualette, M.A., Reyes, J.F.R., Krogh, E., Johansen, S.T., Ciambelli, J.R.P., Rodrigues, H.T., Fonseca, R., 2015. Numerical simulations of high CO2 content flows in production wells, flowlines and risers. In: Offshore Technology Conference, Rio de Janeiro, Brazil, 27-29 October.